Treanor Pujol Ltd manufactures a 155mm Housebeam, 155mm Wide Beam, and a 225mm Deep Beam. These beams are made of prestressed concrete and have an inverted 'T' beam cross-section that enables them to be integrated into composite flooring systems. They are designed in accordance to Eurocode 2 - BS EN 1992-1-1 and manufactured in compliance with BS EN 15037-1 "Precast concrete products - Beam-and-block floor systems - Part 1: Beams".

BEAM & BLOCK FLOORS

The main component of a beam and block floor is the prestressed ‘T’ beams produced by Treanor Pujol. Infill Blocks are placed in between the ‘T’ Beams to produce an immediate working platform. There is also a need for “Slip Blocks” to be laid in the gap which is formed between our Infill Block and the Top of the Dwarf Wall our units are bearing on to.

Under normal residential loading, the 155mm Housebeam can span up to 7 metres while the 225mm Deep Beam can span up to 8 metres. All of our beam lengths are rounded up (or down) to the nearest 50mm.

BEAM & BLOCK FLOORING - THE BENEFITS BEAMS AND BLOCKS ARE EASILY HANDLED AND THEREFORE QUICK AND EASY TO INSTALL ON SITE OFFERING A LOW COST SUSPENDED FLOOR SOLUTION FOR GROUND AND UPPER FLOORS IN BOTH DOMESTIC AND COMMERCIAL STRUCTURES.

- Quick and easy to install

- Immediate working platform

- Units can be fitted in all weather conditions

- Low cost suspended floor solution

- SVP’s are easily accommodated

- All floor finishes can be applied

- Factory produced to high quality standards

TECHNICAL INFORMATION OF BEAM & BLOCK FLOORS

PRESTRESSED BEAMS

Our beams are manufactured with C55 (55 Mpa at 28 days) concrete in accordance with our CE mark and BS EN 15037-1: 2007, prestressed by means of 5mm indented steel wire in accordance with BS 5896 : 2002, having a minimum breaking load of 36.456 kN. Structural design is carried out in our design office in accordance with BS EN 1992-1-1:2004 and its UK National Annex. BS EN 206:2013, BS 8500-1:2005 and BS 8500-2. The cover to the reinforcement is 25mm enabling an XC3 Exposure class, for moderate humidity and external concrete sheltered from rain, as specified in EN 206-1.

In accordance with BS EN 15037-1: 2007 Treanor Pujol beams are manufactured on steel beds by a slip-form process. The enclosed factory environment guaranteeing the prestressed concrete material characteristics and finished product dimensional tolerance.

Slip-form prestressed concrete beams are designed to have a rough upper surface so that if required by design they can be fully integrated into a composite floor.

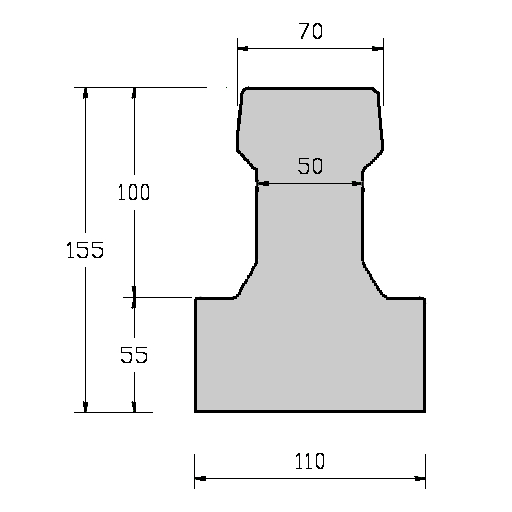

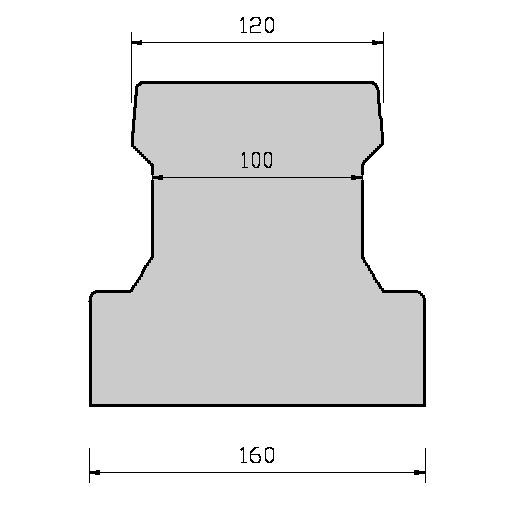

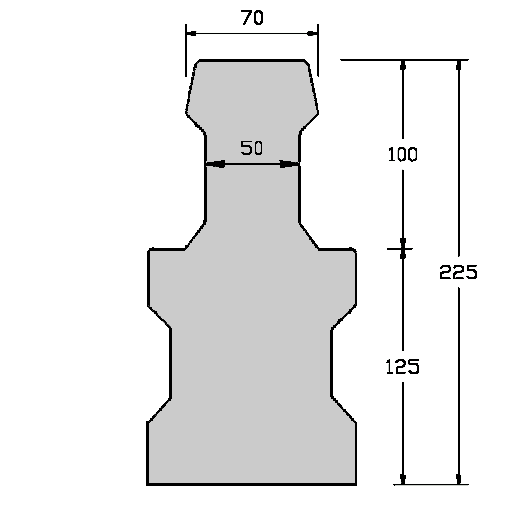

BEAM PROFILES

The cross-section geometry of each beam type is as follows.

BEARINGS

Precast concrete floor beams supported on masonry walls require a minimum “As Built” bearing of 90mm, normally the external supporting walls are the inner leaf of cavity walls. Correct bearing onto internal brick or blockwork walls that are less than 190 mm wide can be achieved by staggering the support of the beams along it.

CAMBER

The prestressed concrete beams have an upward camber, which is maximum at mid-span. Due allowance for the camber of the beams must be made in the depth of finishes with the minimum required depths being at mid-span of the beam. Differential camber between beams will occur where adjacent beams are of different length or in floor areas where there is a change in direction of the beams.

In compliance with BS EN 1992-1-1 cl.: 7.4.3 initial camber in prestressed concrete beams should not exceed span/250.

LOAD TABLES

The following tables show the maximum Total Beam Length, including 100mm support lengths onto masonry walls, for the different beam and block floor distribution Conditions. Designed in accordance with BS EN1992-1-1:2004 for the Permanent Dead Loads, with or without Partitions, and varying Imposed Live Loads.

CROSS SECTION DETAILS

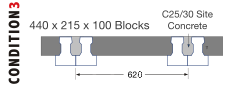

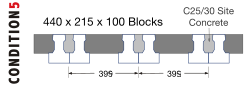

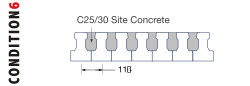

Generic section details for beam and block with different support types are as follows.

Perimeter section - External wall

Perimeter section - External wall

Perimeter section - External wall

Internal section - Internal wall

Internal section - Internal wall

Internal section - Single internal wall

Internal section - Staggered internal wall

Internal section - Internal cavity wall

INFILL BLOCKS

Standard infill blocks, 440mm x 215mm x 100mm , placed between the webs of the prestressed concrete beams are manufactured to BS EN 771-3 from natural aggregates to BS EN 12620, lightweight aggregates to BS EN 13055-1, and Portland cement.

The blocks have a minimum compressive strength of 7.3 MPa. Where blocks are built into load bearing walls the compressive strength must not be less than that of the blocks used in the wall construction. In the case of plantrooms or garage floors the 7.3 MPa block should be used in conjunction with 75mm of structural topping, minimum C25/30 concrete with A142 anti-cracking mesh, to distribute the point loads to the supporting prestressed concrete beams.

Normally the blocks have a density of 1325 Kg/m3 making each block weigh some 12.5 Kg, a comfortable weight for the installation process. In some residential design situations regulations require that a beam and block floor must weigh over 300 Kg/m2 in order to achieve the required sound resistance. In this case a more dense block maybe used, 1950 Kg/m3 in conjunction with the 155 mm House Beam.

SLIP BLOCKS

Slip blocks placed between beam supports to fill the gap beneath the infill block are made with standard solid light aggregate/concrete to BS6073 : Part 1 : 1981. Like the infill blocks, they have a minimum compressive strength of 3.5 N/mm2 or 7.0 N/mm2. The slip blocks for the 155mm House Beam are 172mm x 90mm x 40mm, while the slip blocks for the 225mm Deep Beam are 172mm x 97mm x 105mm.

SERVICES

Blocks can be easily removed in order that service ducts can pass through the floor. Once the required service duct is positioned, the floor can be finished.

GROUTING

Once beams and blocks have been placed, grout is applied as soon as possible to seal the joints. Grout consists of a nominal 3:1 sharp sand/cement mix. Once the surface of the beam and blocks has been “wetted”, the grout is brushed over the floor with a stiff broom. This process ensures that the grout penetrates into the joints to provide an integrated and rigid construction.

FINISHES

All normal finishes (e.g. sand/cement screed, chipboard on polystyrene or battens) can be applied to the top surface of the beam and block floors. When high imposed loads are involved a reinforced structural screed may be used. In the case of domestic garages a 50 mm concrete structural screed with a minimum compressive strength of 30 N/mm² reinforced with A98 steel mesh must be designed. The rough finish provided of Treanor Pujol slip-form beams provides an ideal key for the structural topping in forming a composite floor cross-section.

FIRE

When finished with 13mm plasterboard, Treanor Pujol’s beam and block system provides one hour fire resistance.